TECHNOLOGY

Welcome to the section dedicated to Locatelli Crane’s technology. Locatelli Crane is a reference point in innovation in the field of hydraulic cranes. It is an history of excellence and innovation; we’ve really stood out in technological advancements that have redefined the standards of industrial lifting. Discover how our constant research and development have enabled us to offer cutting-edge solutions, ensuring reliability, high-level performance, and superior quality in every detail. Explore with us the future of handling. Our projects are driven by the passion for engineering and the continuous pursuit of technological excellence.

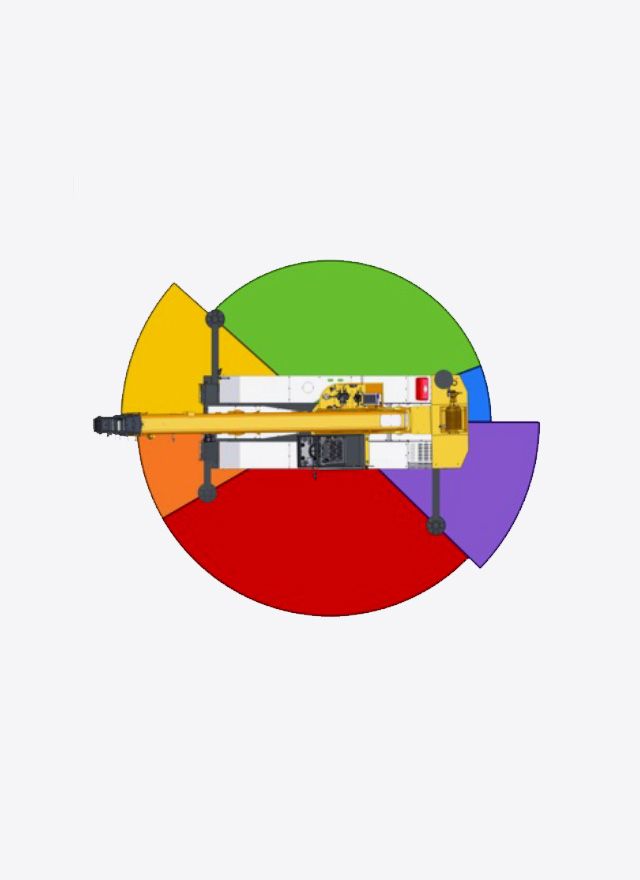

ASYMMETRIC STABILIZATION

The function of asymmetric stabilization represents an excellent technological innovation offered by Locatelli Crane’s cranes. This revolutionary feature allows operators to reduce setup times on the construction site and provides a wider choice of positions, even in tight spaces and congested situations.

Advantages of Asymmetric Stabilization:

- Placement Flexibility: Placement Flexibility: Asymmetric stabilization allows operators to work in conditions of limited space, offering a wider choice of working positions.

- Maximum Safety: The load limiter activates the asymmetric stabilization function when at least one of the outrigger is at a different beam extension than the others. This divides the work area into sectors, allowing operators to work in total safety.

- Maximum Lifting Capacity: The operator can utilize the maximum lifting capacity possible in any situation, ensuring optimal performance even in difficult conditions.

- Optimized Lifting Operations: The asymmetric stabilization function allows for lifting operations that would otherwise be severely limited, ensuring high efficiency and precision.

Thanks to asymmetric stability, Locatelli Crane’s cranes offer excellent placement flexibility and maximum safety for lifting operations. Contact us today to discover how this innovative technology can improve your operations on the construction site!

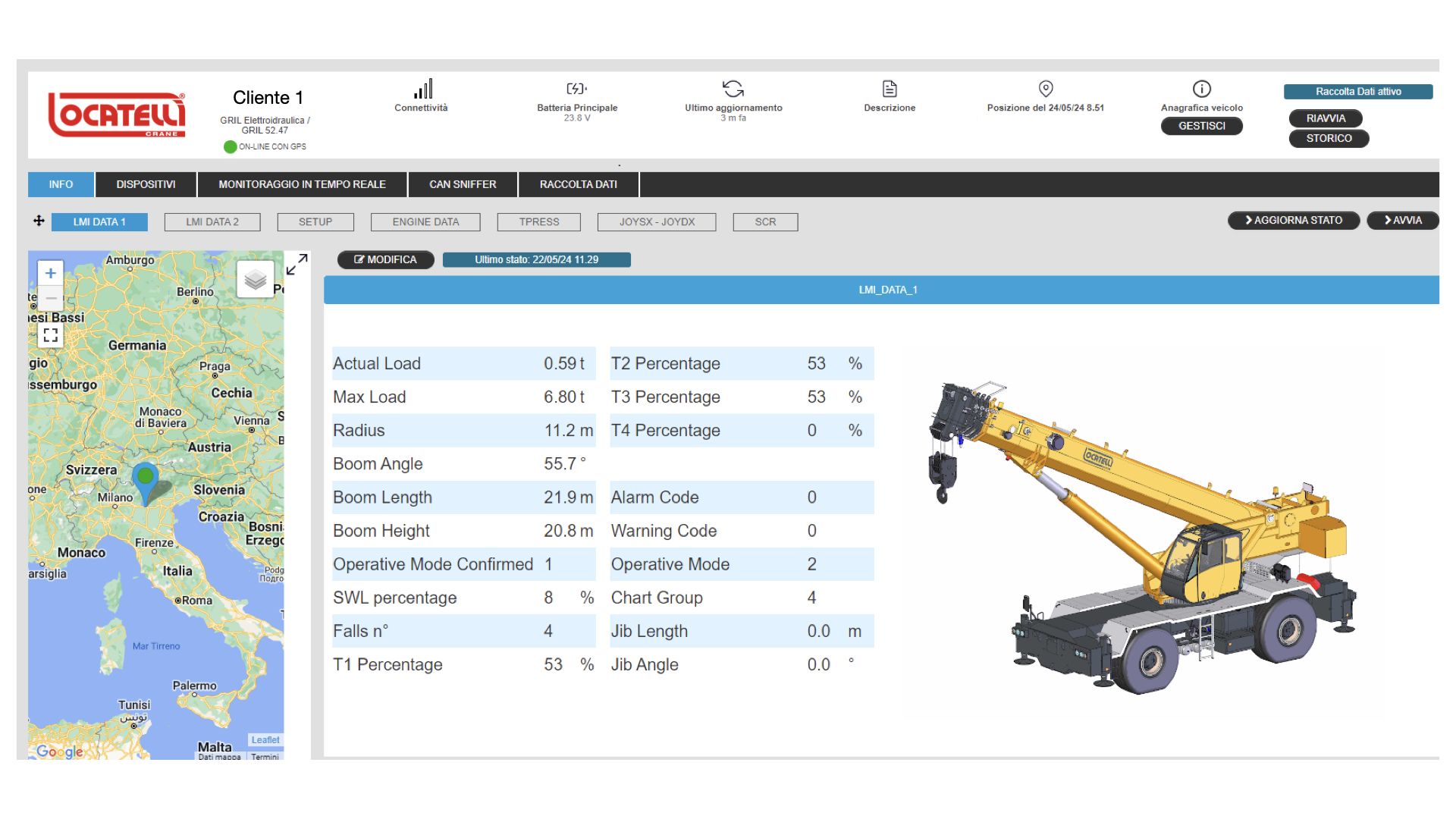

CAN LIVE

Locatelli Crane, the first Italian company in the sector of telescopic hydraulic cranes, stands out for its inclination towards innovation and quality. To ensure maximum safety and efficiency for our customers at work, we have adopted an advanced solution for connectivity and monitoring of our machines.

We have developed a customized system that offers a range of functionalities designed to allow our customers to remotely monitor our cranes, improving fleet management and activity planning.

The adoption of this system is a clear indication of the company’s commitment to providing innovative solutions that enhance operational efficiency and workplace safety for our customers.

GRIL 110.100 BOOM DETAILS

The proposed boom for the new rough terrain crane GRIL 110.100 represents a significant innovation in the sector. With its 5 extendable sections and a length of 47 meters, it offers high versatility and load capacity. The choice to use materials of extremely high resistance, never before employed in similar machines, demonstrates Locatelli Crane’s commitment to researching more efficient and secure solutions.

The double-folded sheet metal, with its reduced thickness, increased safety coefficient, and the shape of the boom section, represents an additional strength in the design, ensuring optimal performance even with considerable extension. The perfect alignment of the elements enhances control and precision in load lifting operations.

The integration of the Load Sensing piston pump, driven by the power take-off of the converter, highlights the focus on energy efficiency and precise control of lifting and handling operations.

In conclusion, the boom of the rough terrain crane GRIL 110.100 stands out for its advanced engineering and innovative solutions adopted. It offers high performance, safety, and optimal operational experience, representing an excellent choice for the most demanding applications in the construction and industrial sectors.

CABIN

Locatelli Crane, the leading Italian company in the production of telescopic hydraulic cranes, continues to impress the market with the introduction of its latest model, the Gril 110.100. This new model marks a turning point in technological innovation and safety in the crane industry, thanks in part to the revolutionary cabin that offers a series of unprecedented advantages.

Specifications

Integrated CAN Technology

One of the distinctive features of the new GRIL 110.100 model is the integration of Controller Area Network (CAN) technology, which enables fast and reliable communication between the various components of the crane. This advanced technology optimizes crane performance, improving responsiveness and reducing response times, resulting in a smoother and more controlled driving experience.

Intuitive Screen and Innovative Controls

The cabin of the GRIL 110.100 is equipped with an intuitive high-definition screen that provides the driver with all the crucial information about the crane in real-time. Thanks to an intuitive user interface and innovative controls, the operator can easily manage crane functions, adjust settings, and monitor performance with precision and ease. Additionally, a global crane control system of the automotive type has been designed through the “TPR” rotary CANbus device, for selecting crane functions and system limitation pages displayed on the screen.

Integrated Maximum Safety

Safety is an absolute priority for Locatelli Crane, and the GRIL 110.100 represents the pinnacle of the company’s commitment to this goal. The cabin is designed to provide a safe and protected working environment for the operator, with advanced safety features including blind-spot monitoring systems, rear-view cameras, and imminent collision alerts. These features ensure greater active safety and reduce the risk of accidents in the workplace.

Conclusions

The new GRIL 110.100 model by Locatelli Crane represents a significant evolution in the landscape of telescopic hydraulic cranes. With its cutting-edge cabin equipped with CAN technology, intuitive screen, innovative controls, ergonomic seat, and advanced safety systems, the GRIL 110.100 offers superior performance, greater efficiency, and maximum safety on the construction site.